Weekly Welcome

Hello Reader

I presented to an excellent crowd at the premiere Precision Ag 2.0 conference in Calgary last week. I also had a great sit down with industry and government researchers to look at canola vacuum planter trials for 2012. Monosem has offered a 15-foot vacuum planter to begin trial work at Lacombe Research Station and the project has good momentum.

In this week’s issue of Beyond Agronomy News, I’ll pass along my notes from the Precision Ag 2.0 conference and then jump into shallow banded urea losses. Next, we’ll look at the cost and value of setting up your own protein and moisture tester in a post-CWB world. We’ll finish with technical grain market news.

Have a great week.

Take home notes from Precision Ag 2.0

1. If you don’t have yield monitors and you are doing VR, you have it upside down.

2. Management should be applied first and precision farming second.

3. A new controller is available for Lindsay Zimmatic irrigation pivots that can do variable rate irrigation and variable rate fertigation at the same time.

4. 50% of phosphorus uptake in wheat is taken from below 4 inches.

5. 58% of soils in Alberta test below critical levels for phosphorus (10 ppm/ac). 82% of Saskatchewan soils test below critical P levels and 57% in Manitoba.

6. The key to maximizing VR is to match below ground variability (soil, topography, nutrients) with above ground variability (growing season precipitation, plant response to environment).

7. Differentiate your business or disappear! Brent Vankoughnet

8. When it comes to land rent deals, keeping it complicated is the smart farmer’s advantage. Smart farmers lose when deals become simple.

9. You need a seedbed utilization of 25% or less (shank width ÷ row spacing) to inter-row seed successfully. SL

How much nitrogen are we losing with shallow banded urea?

Low draft openers called into question on nitrogen use efficiency

Low draft openers called into question on nitrogen use efficiency

There has been a large shift toward low draft, double shoot openers in no-till farming across the Prairies over the last seven years. Low draft, double shoot openers are different than conventional double shoot openers because they separate nitrogen and seed horizontally rather than vertically. With conventional double shoot openers, nitrogen used to be placed roughly 1 to 1.5 inches below and to the side of the seed. Today’s low draft openers place nitrogen just ½ to ¾ inches below the seed and use ¾ inch of horizontal separation to reduce seed burn from high nitrogen rates. Ag Canada research published in 2010 suggested we could be losing up to 35% of the nitrogen we apply to volatilization when we band urea at depths of 1 inch or less.

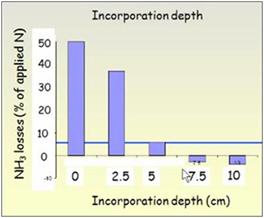

The chart you see here is from research done by Dr Phillip Rochette from Ag Canada in Quebec and shows the amount of nitrogen lost as NH3 when banded at depths of 0 cm, 2.5, 5, 7.5 and 10 cm depths. You can see that up to 50% of the urea is lost when applied at the surface, 35% is lost when banded at 2.5 cm or 1 inch and falls below 5% NH3 loss when banded at 5 cm deep or 2 inches. Dr. Rochette revealed that the process of hydrolysis increases the pH in the soil around the urea which in turn increases the amount of NH3 present in the soil, even in acid soils below a pH of 6.

To explain hydrolysis, in a nutshell, here is what’s happening to urea when banded in the soil at 1 inch or less with a low draft opener:

1. Urea is banded beside and slightly below the seed at a depth of approximately 1 inch.

2. Urease enzymes help break down urea to ammonia (NH3) in a process called hydrolysis.

3. The process of hydrolysis consumes a hydrogen ion which increases the pH of the soil around the band of urea.

4. The pH of the soil remains elevated around the urea band for up to 25 days.

5. The balance of nitrogen in the soil shifts towards ammonia at high pH’s and makes shallow banded urea at risk of volatilization even though it is placed in the soil.

6. NH3 escapes through the highly porous layer of top soil found in the top inch of soil.

If these results are occurring with our very common low draft, shallow banded urea openers, we could be looking at losses of up to 30% of what we apply. It may not be that high in our soils in Western Canada but at $65.00 an acre in nitrogen costs we better be sure we’re not throwing $22.00 an acre out the window and the yield and protein that goes with it.

There are two solutions to prevent volatilization from banded urea. One is to place urea below two inches deep. The other is to apply Agrotain to urea to slow hydrolysis down and prevent the spike in pH that increases volatilization.

I can’t attest the extent of nitrogen volatilization with low draft openers on our soils but this research has me questioning the opener’s effectiveness.

Video of presentation by Dr. Phillipe Rochette

Chart: Rochette et al 2010

Protecting your price risk with an accurate protein and moisture tester

In a post CWB market, it will be extremely important to understand your HRS grades and protein levels prior to delivery to avoid serious revenue losses. I think most people by now have seen the projected price spreads which range from $18.00 to $27.00/MT. Worst of all, the protein spreads can’t be guaranteed when you forward contract so we’re all left a little out in the open when it comes to managing protein risk.

In a post CWB market, it will be extremely important to understand your HRS grades and protein levels prior to delivery to avoid serious revenue losses. I think most people by now have seen the projected price spreads which range from $18.00 to $27.00/MT. Worst of all, the protein spreads can’t be guaranteed when you forward contract so we’re all left a little out in the open when it comes to managing protein risk.

The same holds true for malt barley where loads can be rejected at the elevator, forcing you to bring it home or sell it locally to a feedlot at a discount. Either way, it could be time to invest in your own protein and moisture tester.

I’ve looked in to near infrared (NIR) protein and moisture testers and discovered that the CGC and the CWB use the Infratec 1241 model from FOSS. The Infratec 1241 is also approved by the USDA. FOSS has two options on the market:

Infratec 1241 : $40,000-$45,000 USD and can test wheat, barley, canola, peas, flax and lentils. It’s a very diverse and accurate grain protein tester.

Infratec Sophia : $19,000 US and tests just wheat and barley. It’s a very accurate lower cost option if you’re biggest discounts for protein come with wheat and barley.

Let’s run some numbers on how many loads it would take to pay for each tester if you delivered HRS wheat at 1% lower protein than contracted.

Steve’s quick math

Discount on 1% lower protein = $18/ tonne

44 tonne load × $18.00/tonne discount = $792/ load

Infratec 1241: $45,000 ÷ $792 = 57 loads

Infratec Sophia: $19,000 ÷ $792 = 23 loads

In this scenario you would need to avoid a 1% protein discount at $18 tonne on 23 loads to pay for the Infratec Sophia and 57 loads to pay for the Infratec 1241. The best risk management program in a post-CWB world is to know your protein levels before they hit the elevator. Having the same protein and moisture tester the CGC and CWB use puts you in the driver’s seat and helps you avoid delivering off speck wheat which can come with heavy discounts. I’ve heard of a few deliveries this year with unexpected protein levels below 10% at a discount less than the price of feed. Ouch.

The way I see it, there’s no reason a group couldn’t come together to purchase a unit to offset the cost. It takes 50 seconds a sample to know exactly what you have in each bin and the portable tester can be parked at any location. Also, John Folino at FOSS tells me there are government grants available to help offset the cost of the grain testers. SL

For more information contact John Folino at FOSS

Phone: 1.800.547.6275 ext. 313

Mobile: 647-339-5055

Fax: 1 (952) 974-9823

Email: jfolino@fossna.com

Photo source:FOSS

Market News

Technicals

Canola Nov12: The long and short term trends are up.

Wheat Dec12: The long and short term trends are down.

Corn Dec12: The long and short term trends are down.

Soybeans Nov12: The long and short term trends are up.

CDN$ Mar12: The long and short term trends are up.

USD Mar12: The long and short term trends are down.