Agronomist notes

Hello Reader,

Hello Reader,

I had a great time in Houston last week and was well received with my presentation on high yield malt barley production. The first four hours of talks on plant nutrition and plant hormones with bar charts, line graphs and more bar charts had my head spinning. However, when the dizziness subsided, I did have a better understanding of nutrient and hormone interactions. Most of all, though, I gained a fresh perspective on late season nutrition and ways to improve yield and profitability at unconventional growth stages such as late-podding or post-flowering in cereals.

In this issue, we’ll look at late season nitrogen application in peas to boost yields. Next, we’ll go through the trial data which lead to 178 bu/ac oat yields. Oats, that’s right, I said oats! Last, I’ve got some fantastic tips on the use of vacuum planters in canola, gleaned by Corey Jespersen from Spruce Grove on a recent trip to St Louis. We’ll finish with technical grain market news.

Have a great week. See you at Farm Tech.

Do high yielding peas require late season nitrogen?

There is a growing practice of applying late season nitrogen to high yielding soybeans at the pod fill stage in the US. Research from Better Crops/Vol. 85 (2001, No. 2) suggests that soybeans may not be able to supply enough nitrogen during peak demand via atmospheric N2 fixation when yields climb above 55 bu/ac. So now I must ask the question, can we boost yields in field peas from late season nitrogen applications? Let’s look through the nitrogen demands of field peas, the limitations to N fixation and determine if we’re missing a crucial piece of the puzzle when it comes to pea yields.

There is a growing practice of applying late season nitrogen to high yielding soybeans at the pod fill stage in the US. Research from Better Crops/Vol. 85 (2001, No. 2) suggests that soybeans may not be able to supply enough nitrogen during peak demand via atmospheric N2 fixation when yields climb above 55 bu/ac. So now I must ask the question, can we boost yields in field peas from late season nitrogen applications? Let’s look through the nitrogen demands of field peas, the limitations to N fixation and determine if we’re missing a crucial piece of the puzzle when it comes to pea yields.

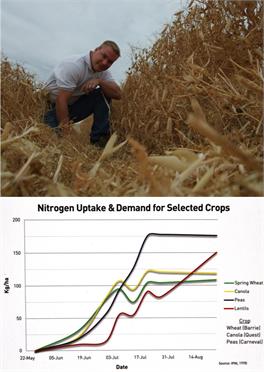

The nitrogen demand curve for peas is massive and unlike any other crop we grow. For example, a 65 bu/ac pea crop will require upwards of 218 lbs/N/ac which is 3.3 lbs/bu. The chart you see here shows the nitrogen demand curves for wheat (green line), canola (yellow), peas (blue) and lentils (red) throughout the growing season. The crop with the highest nitrogen requirement is peas with the greatest demand through the month of July, then leveling off in August.

We largely ignore nitrogen demand in peas because they fix their own naturally from the atmosphere. We apply Rhizobium innoculant at planting to ensure adequate bacteria which in turn supply the plants with adequate nitrogen. However, nitrogen fixation can be reduced with pH’s below 7, high soil aluminum levels which is driven by low pH, water logging and poorly aerated soils. The reason soil aeration is so important is because Rhizobium bacteria fix nitrogen from the air in the soil surrounding the roots. We always think about fixing nitrogen from the atmosphere but in reality, it’s from the air contained in the soil. You can have all the nitrogen in the world in the atmosphere, but if you don’t have a place to store it in the soil, you’re at a disadvantage. That’s where late season nitrogen tops ups in July or early August may come in to play.

The research work done on soybeans in the US looked to have gained an average of 6 bu/ac when applying 20 lbs/N/ac as UAN. To apply UAN late season in peas, it would require streamer nozzles or dribble band nozzles to avoid leaf burn and have the droplets roll off the leaves. It would also need to be applied early morning or late evening to reduce leaf burn. The success of the practice still hinges on rainfall to wash the nitrogen in the soil which makes it difficult to predict optimum timing. Let’s run the numbers at today’s yellow pea and nitrogen prices to see where the breakeven is.

Yellow pea: $6.98/bu, October delivery

UAN: $0.70/lb × 20 lbs/N/ac

Application: $8.25/ac custom rates

Total: $22.25/ac

In this example, you would need a 3 bu/ac yield increase to cover costs and a 6 bu/ac increase to generate a 2:1 return on your investment. If you are growing peas in soils with high aluminum, pH’s below 7 and certainly below pH 6, water logged or compacted soils, perhaps a late season nitrogen application is what you need to drive yields higher. The nitrogen rates and crop staging would have to be fine tuned but I think it could be an opportunity to grow yield at a stage we often ignore. SL

Pictured above: Nitrogen demand curves: IPNI

High yield oat production

In my area, there is an ignored and often mistreated crop called oats, also known as the ugly second cousin to feed barley. It is typically planted for green feed or late season default crop because the window closed on wheat and canola timing. What if I told you that oats can be a profitable crop with a genetic potential to yield over 250 bu/ac? What if you treated oats with the same respect as wheat or canola? Well, agronomist Dan Owen from Hudye Soils in Norquay, SK did just that and hit an incredible yield of 178 bu/ac in 2011. Best part is, he’s only getting started.

Here are the details to the yield busting crop:

Variety: Triactor

Target plant density: 32 plants/ft2

Seeding rate: 106 lbs/ac

Fertility: 128-41-92-40

Seeding Date: May 9th – 15th

Seed Treatment: Raxil MD & MP Superstarter @ 216bu/jug

Crop Protection: Roundup Transorb, post-seeding/ pre-emergence

Herbicide: Refine M for weeds, Tilt @ 1/3 rate, MP Copper @ 1/3L, MP Managanese @ 1/2L, MP Zinc @ 1/3L

Fungicide: Caramba @ 2/3 rate, Golden Harvest @ 1/2L, Polyamines @ 1/4L

Desiccation: Roundup Transorb @ 67 L/ac

Yield: 178.8bu/ac

The limiting factor like most of our cereal varieties is lodging. To achieve yields above 200+ bu/ac you need to keep plant densities high which increases competition for sunlight, nutrients and water. Dan has been testing growth regulators on oats in their Field of Dreams field scale trials and hopes that some of the PGR’s they’ve been testing will gain registration.

The other limitation to high yields is growing season and uncontrollable factors like early and late season frost. Oats are usually perceived as a short season crop but a high yielding oat variety like Triactor requires 110 days much like wheat or canola. A simple move of seeding date could generate higher yields and with a little TLC, oats could bring good margin to the rotation.

Let’s run the numbers on milling oats:

Feed Oats: $2.98/bu

Steve’s COP: $300.00/acre including land rent & $93.00/ac fertilizer.

Breakeven: $300.00 ac ÷ $2.98 = 100 bu/ac

30% margin: =$300.00/ac × 30% ÷ $2.98 bu + 100 bu/ac breakeven = 130 bu/ac

Keys to success

First, you need to start with a strong plant stand density with a target of 32 plants per ft2. Next, a high yielding oat crop requires a strong fertility program. Oats respond well to copper and manganese as well as nitrogen and potassium, especially when pushing yields past 150 bu/ac. After a strong fertility package follow up with a fungicide program will be important. Fungicides like Caramba are exceptional at controlling leaf diseases in oats and also help reduce lodging. Some choose to apply Tilt at herbicide timing to help control leaf disease early on. Last, if possible apply a high rate of glyphosate prior to seeding and another application prior to emergence to help with wild oat and weed pressure.

We’re in an area that can typically produce 100+ bu/ac oats with ugly second cousin agronomy. However, if we start paying attention I can see yields hitting 150 or 200+ bu/ac with the same or slightly more rainfall. Really, hitting 200+ bu/ac in some areas is not out of reach. According to BASF, a producer hit 200 bu/ac oats in Manitoba back in 2009 and Canterra claims it reached 234 bu/ac at its CPS site near Didsbury, AB in 2011. I’m sure there are many stories of 200+ bu/ac oats across the Prairies. With the right agronomy, perhaps oats might make a comeback into the rotation. Time will tell and I’ll keep you posted on the results. SL

Tips on vacuum planters in canola

You wouldn’t believe how much interest and how many conversations I’ve had about vacuum planters in canola. I think it seems logical to most to start treating canola with the same precision as corn and soybeans. I had a flood of information come in last week which has me talking about precision planting equipment from Illinois and some ways to get into vacuum planters at a 1/5 of the cost I’ve quoted in earlier issues for a planter like the Monosem.

You wouldn’t believe how much interest and how many conversations I’ve had about vacuum planters in canola. I think it seems logical to most to start treating canola with the same precision as corn and soybeans. I had a flood of information come in last week which has me talking about precision planting equipment from Illinois and some ways to get into vacuum planters at a 1/5 of the cost I’ve quoted in earlier issues for a planter like the Monosem.

Corey Jespersen who farms near Spruce Grove recently took the opportunity to visit with the folks at Precision Planting in Tremont, IL. They demonstrated the use of their technology that adapts to JD and Case planters to improve seed singulation and they also shared a tonne of great tips on how to set up your planter to meter canola efficiently. Here are the tips and tricks that Corey learned on his trip:

• Canola at up to 85,000 seeds per pound will work. Anything over 85,000 per pound will plug up the disk because there are too many small seeds jamming in the holes.

• Setting a low vacuum pressure is key at somewhere close to 4lbs. High vacuum pressure causes air to be drawn up the seed tube and the seeds bounce around like popcorn, swirling in the air and not falling straight down.

• Precision Planting has a specialty extractor that keeps the holes (55,000th of an inch) clear.

• Using an 80% talc-20% graphite lubricant is necessary to eliminate static and to lubricate.

• Calculating the number of seeds per acre is necessary to set up the monitoring equipment from Precision Planting.

• John Deere 1870 planters on 15-inch row spacing can be found easily and are relatively cheap. Look on Iron Search

Calculating seeds per acre and seeds per ft of row:

Seeds per foot of row = [seeds/acre]/43,560] x [row spacing/12]

Calculating plant population per acre is equal to:

[43,560 ÷ (row spacing in inches ÷ 12)] X plants per foot of row

Calculating seeds per pound by thousand kernel weight:

454 g/lb ÷ g/tkw x 1000 = seeds/lb

I’ve uploaded a YouTube video showing how the canola seed singulation works on a Precision Planting system. It’s short and sweet but you can seed the amazing singulation their metering system offers. Their metering system can be bolted on to any JD or Case IH planter. The cost of the system is roughly $125 per row plus the monitor.

Thanks to Corey, we’ve discovered a way to buy affordable JD and Case IH vacuum planters from the US and add a Precision Planting adapter and canola disk to begin planting. Plus, we’ve got a few tips to avoid some costly mistakes and help tweak the planter to the right settings. I think we’re on the right track and I’ll keep you posted on more information as it rolls in. SL

Pictured above: Precision Planter 60 hole canola disk.

Market News

Technicals

Canola: Nov12: The long term trend is down and the short term trend is up.

Wheat: Dec12: The long and short term trend is down.

Corn: Dec12: The long and short term trend is down.

Soybeans: Nov12: The long term trend is down and the short term trend is up.

Canadian Dollar: Mar12: The long term trend is down and the short term trend is up..

USD: Mar12: The long term trend is up and the short term trend is down.