Weekly Welcome

Hello Reader

I always enjoy sitting down to talk shop with my clients. Lately we’ve reviewed crop plans, variety selection, seeding rates and fertility plans. It’s amazing to see the difference in thousand kernel weights this year between location and variety. So far the biggest difference is between AC Harvest and Stettler wheat, a whopping 27%. Those seeding by the bushel will be very disappointed in their plant stands. The retailers are talking about rising nitrogen prices for whatever reason, but I guess it’s close to spring so demand will increase shortly.

Mitch and I are on the hunt for a 3640 Spray Coupe and we’re comparing the GreenSeeker to the OptRx system as a crop sensor to do in-season variable rate inputs. We’ll make that decision shortly.

This week we’ll look at the effects of high temperature on wheat yield, something that’s sure to surprise many. Next, I’ll focus in on a new technology that measures compaction and reveal some interesting findings on the compaction potential of sandy soils. Last we’ll quickly review what I feel is a stellar disc drill design that follows the ground amazingly at fast seeding speeds. We’ll finish with technical grain market news.

Have a great week.

High temperature effects on wheat yield

One of the biggest limiting factors to achieving maximum yield in wheat is high temperature stress. It’s hard to believe that temperature would play a significant role in Prairie wheat production but wheat is a cool season crop that prefers temperatures below 20°C. To put it in perspective, head size in wheat is strongly affected by air temperature and to a lesser extent nitrogen and water. On our quest for high yielding wheat, I think it is important to understand what determines head size and what can be done and when to encourage head development. Today I’ll outline some key points on the effects of temperature on head development and outline potential management strategies to reduce heat stress.

One of the biggest limiting factors to achieving maximum yield in wheat is high temperature stress. It’s hard to believe that temperature would play a significant role in Prairie wheat production but wheat is a cool season crop that prefers temperatures below 20°C. To put it in perspective, head size in wheat is strongly affected by air temperature and to a lesser extent nitrogen and water. On our quest for high yielding wheat, I think it is important to understand what determines head size and what can be done and when to encourage head development. Today I’ll outline some key points on the effects of temperature on head development and outline potential management strategies to reduce heat stress.

The development of head size:

• The growing point of the plant is called the apex which quickly becomes the head (spike) of spring wheat.

• The apex develops in two distinctive stages: 1) vegetative, 2) reproductive.

• The first stage initiates the development of all 8 leaves that grow on a wheat plant.

• The first stage occurs in the first 17 to 21 days after emergence.

• At the 4 to 5 leaf stage (GS 14-15) wheat switches from the vegetative phase to the reproductive stage and seed-bearing spikelets form on the apex.

• Each spikelet has a potential to produce 5 kernels.

• Spring wheat can produce roughly 18 spikelets per head (18 x 5 = 90 kernels/head)

• The terminal spikelet formation on the head ends at the 6-leaf stage, roughly 26 to 29 days after emergence.

The effects of temperature on head size:

• The critical period in determining the number of spikelets per head occurs during the 5 to 6-leaf stage (GS 15-16)

• The number of spikelets formed on each head is strongly influenced by air temperatures above 20°C and to a lesser extent nitrogen and water.

• As air temperature increased above 18°C during the 5 to 6-leaf stage, the number of spikelets per head decreased and resulted in lower grain yield potential.

The effects of temperature on kernel number and weight:

• Research has shown wheat grown at 25°C during flowering had only 40 percent of the kernel number in the main spike when compared with plants grown at 15°C.

• Over the range of a 12° to 26°C increase in mean temperature during grain filling, grain weight is reduced at a rate of 4 to 8 percent/°C.

The reason why yield declines under heat stress is because of a hormone imbalance. When plants fall under heat stress the proteins inside hydrolyse to ammonia. The build up of ammonia is toxic and causes the plant to produce the hormone ethylene, which eats up cell wall tissue and causes premature ripening. The trick to managing heat stress is to reduce excessive ethylene production.

Two ways to reduce heat stress are direct seeding and early planting. Early planting allows the plants to reach tillering by the end of May or early-June before average temperatures above 20°C usually occur. Direct seeding uses residue cover to help reduce evaporation and help keep the soil cooler. The addition of soil moisture and reduction in soil temperature helps the plant buffer against temperatures above 20°C.

The next answer to managing heat stress, and one many product companies are working on, is the use of specific compounds and plant hormones. I haven’t used or recommended products for reducing heat stress but I have found a few to try:

• Fulvic acid reduces heat stress. Fulvic acid was sprayed on plants just before head development, and allowed to grow to maturity over time when hot, dry winds are prevalent. It was found that grain yield increased by 7% to 18% over the untreated controls. Xudan (1986)

• BioForge by Stoller is used in the US to treat excessive ethylene production.

• Action 5X sold by Stoller in Canada is said to maintain fertile pollen and ovaries under high temperatures during head development and ripening.

Some research suggests that strobilurin fungicides do little to reduce ethylene production when plants are under heat stress. Products like Headline, Quilt and Stratego which claim to reduce ethylene should be used with caution as they work best when disease is present.

Managing heat stress in the future will not only remain in the hands of genetics, it will come from the timely application of products that allow plants to tolerate heat stress. In the mean time, we can do our best to seed early and maintain residue to help keep plants cool but we can’t plant everything early and the evenness of our residue spread leaves little to be desired.

When you look at the genetic potential of 90 kernels per head in HRS wheat and the 25 to 30 kernels we achieve today, we have a long way to go. The subsequent 4% to 8% yield loss each time the temperature climbs 1°C during grain fill has me wondering what we can do to help protect yield during grain fill when temperatures typically hover between 20°C and 30°C. With nitrogen and water availability second to the importance of air temperature, I’d say it’s worth finding ways to reduce heat stress throughout the growing season. SL

Sandy soils are prone to compaction

Uncovering compaction through new technology

What are the yield limiting factors in sandy soils? Poor water holding capacity? Poor cation exchange capacity? How about a third factor, compaction. There is a common misconception that sandy soils are less prone to compaction compared to clay soils. In reality, sandy soils are more prone to compaction because they don’t swell and contract like clay soils and wheel slippage tends to be higher. I uncovered some interesting results from our CTFA project that support my theory and potential solution.

What are the yield limiting factors in sandy soils? Poor water holding capacity? Poor cation exchange capacity? How about a third factor, compaction. There is a common misconception that sandy soils are less prone to compaction compared to clay soils. In reality, sandy soils are more prone to compaction because they don’t swell and contract like clay soils and wheel slippage tends to be higher. I uncovered some interesting results from our CTFA project that support my theory and potential solution.

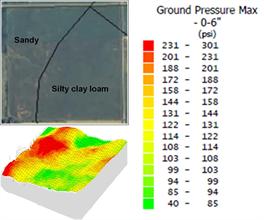

Our CTFA committee hired Colin Bergstrom of Point Forward Solutions to measure compaction on a 1 acre grid pattern. Colin uses an Amity electric over hydraulic penetrometer that measures psi readings down to 18 inches. The multi-coloured compaction map above shows psi readings from 40 to 301 at the 0 to 6-inch depth. The field sampled is shown in the aerial photo from the AGRISID database and outlines where the sandy soil texture is located on the west side of a 160 acre field. It should be noted that the highest psi readings occur along the west side where the ridge of sandy soil exists.

Research from GRDC in Australia supports the theory that sandy soil textures do compact and can be repaired through deep ripping. The research found that grain yields are most likely to improve from deep ripping on sandy soils compared to any other soil texture. I would argue that controlled traffic farming would avoid creating the problem in the first place but for now, let’s focus on selective treatment of deep ripping on compacted areas in sandy soils.

Here is what I suggest. First, itemize the fields with sandy soil ridges and locate those areas using AGRISID. Next, in the field dig down 24 inches in a few areas and run a buck knife from the top of the profile downwards and from the bottom upwards. The buck knife should stop at the zone of compression and you’ll know how thick the compaction layer is if it exists. Next, hire a consultant with an EM38 to develop a soil texture map and if possible, hire a consultant to develop a compaction map like the one you see in the photo above. Once the sandy soil zones are located, you can selectively deep rip those areas rather than ripping the entire field. Let’s run the numbers on this theory.

Let’s assume there is 40 acres of sandy compacted soil inside a 160 acre field and deep ripping costs are $70.00 per acre. We’ll compare that to no mapping and deep ripping the entire 160-acre field.

Steve’s quick math

EM38 soil texture map and PSI compaction map on 160 ac field = $2,500

Selective deep ripping: 40 acres x $70/ac = $2,800

Total for selective deep ripping treatment: $2,500 + $2,800 = $5,300

Breakeven: $5,300 ÷ 160 ac = $33.12

Total for deep ripping 160 ac = $70.00 ac

In this example, you would save $36.88 per acre in selective deep ripping costs and target the areas that respond the most to deep ripping. You would also save 80 hours in labour not having to deep rip the additional 120 acres at 1.5 mph where a crop response is unlikely to show.

Sandy soil textures are prone to compaction from increased wheel slippage and the lack of expansion and contraction in coarse textured soils. This relatively new tool called compaction mapping can hone in on areas with high compression readings and analyze them against NDVI imagery, yield maps, soil texture maps and topography maps. In this example, we were able to match high compression readings with sandy soil texture and provide a potential solution to help generate higher yields. So, the next time you decide to reduce your inputs in a lower yielding sandy soil Zone 1, perhaps take another look to see if compaction is your limiting factor. Maybe a selective variable rate deep ripping program will net you greater results than simply applying less fertilizer. SL

Pictured above: AGRISID aerial map and psi compaction map.

Walking beams are the ticket for speed and accuracy at seeding

I’ve been battling back and forth on Twitter about the need to gain speed and accuracy with our seeding systems. As it stands, the focus on efficiency with seeding tools is about wider drills and tyne openers rather than discs. I think that tyne opener will always be limited by speed because they throw dirt at higher speeds and lose seed placement at the same time. Disc drills on the other hand have the ability to maintain seeding depth and accuracy at much higher speeds. In my opinion the next revolution in air drills will be to pair width with speed and that can only be done with a disc opener.

I’ve been battling back and forth on Twitter about the need to gain speed and accuracy with our seeding systems. As it stands, the focus on efficiency with seeding tools is about wider drills and tyne openers rather than discs. I think that tyne opener will always be limited by speed because they throw dirt at higher speeds and lose seed placement at the same time. Disc drills on the other hand have the ability to maintain seeding depth and accuracy at much higher speeds. In my opinion the next revolution in air drills will be to pair width with speed and that can only be done with a disc opener.

I reviewed Nuffield Scholar Stephen Balls paper to look at disc drill designs after he had the opportunity to travel around the world looking at disc drills. The design I’m most impressed with is the one produced by AVEC in South America. Here are Stephen’s comments on the benefits of AVEC disc drill with a walking beam assembly:

“The benefit of this method of attaching the assembly as shown in the picture allows the discs and closing mechanism to be truly ground following. The double disc assembly is connected to the walking beam and the beam then attaches to the main frame. In the model from Avec, all of the down pressure came from an air over hydraulic system for dampening and keeping each unit independent. With a large number of double disc units, the depth control wheels are connected at the rear behind the discs. This creates a pushing motion and a separating force pulling the depth control wheels away from the discs. Trends in the new designs incorporate a forward fixing point. The force generated by pulling rather than pushing the depth control wheels keeps them tight against the disc which reduces strain and fatigue on the steel. It can also help with cutting action applied to the residue.”

The problem with most disc opener assemblies is the angle at which they attack the ground. An improper angle can lead to uneven seeding depths in unlevel fields especially at fast traveling speeds. Stephen included comments from Dwayne Beck, Dakota Lakes Research Farm, on his opinion of the assembly attachment styles of certain disk drills:

1. The JD and similar machines have radial attachments, which mean the angle of attack is correct for only one spot in its travel.

2. The parallel (or parallelogram) linkage has the proper angle of attack as long as the frame of the implement is parallel to the soil surface (very level fields).

3. The walking beam attachment has the proper angle of attack at almost all times.

The future of seeding efficiency lies in the merging of speed and width and can only be achieved with proper disc drill assemblies. I believe the Avec walking beam disk opener assembly is brilliant and I just wanted to show you an example of what’s out there besides North American drills. My goal in the next ten years is to get a speeding ticket during seeding and still maintain accurate seeding depth. I suspect the walking beam would help achieve that goal. Take notice red, green and blue! SL

Pictured above: Avec disc drill walking beam taken by Stephen Ball.

Market News

Technicals

Canola Nov12: The long and short term trends are up.

Additional Image Details

Wheat Dec12: The long term trend is neutral and the short term trend is up.

Corn Dec12: The long term trend is down and the short term trend is up.

Soybeans Nov12: The long and short term trends are up.

Candian Dollar Mar12: The long term trend is up and the short term trend is down.

USD Mar12: The long term trend is neutral and the short term trend is up.